Hamburger Containerboard: experience with an innovative cooking process for starch

As early as 2022, the Hamburg-based group decided to process starch using the innovative and patented cooking process from PGA Anlagenbau GmbH at its Gelsenkirchen site.

The reason for the investment was the desire to significantly increase the efficiency of starch processing and thus the efficiency of the site itself. In particular, the consumption of steam and starch was to be reduced as much as possible. In addition, the aim was to improve the quality of the starch that had already been processed and to prepare a homogeneously cooked starch without a swelling agent for the ASA plant.

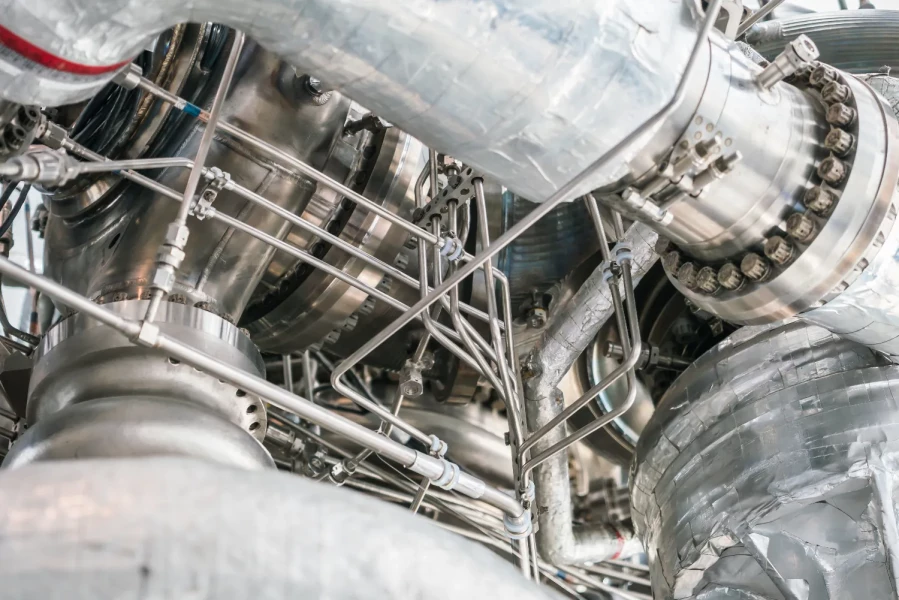

This cooking line has been in successful continuous operation since the beginning of 2023. The centerpiece of the line is the PGA starchPERFORMER. The starch digester is based on a patented thermo-mechanical cooking process and is revolutionizing the processing of corn starch and surface starch in the pulp and paper industry. Compared to conventional cooking systems, the PGA starchPERFORMER significantly reduces steam consumption while producing completely homogeneously cooked starch. In addition, the system offers maximum flexibility when using different types of starch and enables a quick change between different types. The enzymatic starch degradation process is fully under control with the PGA starchPERFORMER. The starch binding capacity is used more efficiently and the molecular weight distribution is also regulated. This can significantly reduce the amount of starch needed.

This presentation will first examine the initial situation and the optimization measures taken in starch processing at the Gelsenkirchen site. This is followed by a technical explanation of the starch processing with the help of the PGA starchPERFORMER, and finally by the operating experience with this innovation.

PGA Anlagenbau GmbH is part of the IBS Paper Performance Group, based in Teufenbach-Katsch, Austria.