Flexible power management through IR deep drying

Paper production is highly energy intensive. A good two thirds of energy consumption is used to dry the paper and coatings. The vast majority of this energy is currently generated using fossil fuels.

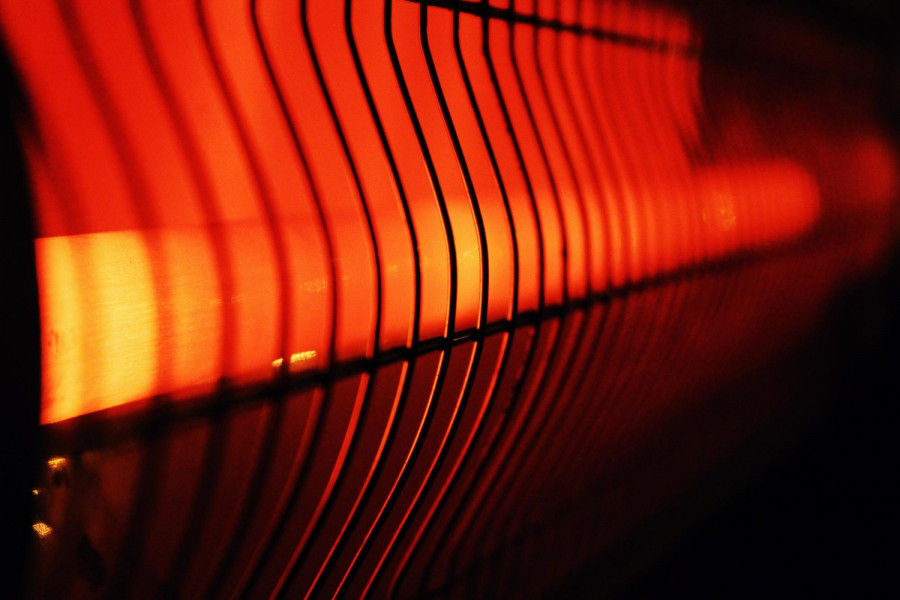

To decarbonize the paper industry, these fossil fuels must be replaced by electricity that can be generated from renewable sources. Today, electric drying is still in its infancy, with the exception of infrared drying. However, conventional NIR emitters are relatively inefficient, making them insufficient for drying.

Compact Engineering's eNIR dryers typically vaporize twice the amount of water with the same amount of energy, making them competitive with fossil drying. Above all, the radiation penetrates deep into the substrate and dries from the inside out.

We show how these energy-efficient dryers can be used as catalysts for drying cylinders and gas-powered hot air hoods. The catalyst effect significantly reduces the energy requirements of the following cylinders and/or hot air hoods.

Profile control with eNIR dryers instead of overdrying with fossil energy reduces the need for fossil energy by a similar amount. Together, the steam requirement can be reduced by 15% to over 30%.

It is already possible today to choose between fossil and renewable energy and, depending on the cost of the electricity, to control the drying of the paper machine in such a way as to reduce costs and, above all, CO2 emissions.

Together with the digital twins from AutomationX, the conversion of reject pulp into fuel pellets and the heat pumps from BM Green Cooling, the biggest part of a paper mill's fossil energy requirements can be electrified in this way.