Board quality advisor for the fiber industry

A part of the process industry, the fiber industry is exposed to the trend of producing consistency high quality products with fluctuating raw material qualities and increasing quantity with decreasing qualified workforce as well as limited financing. In order to compensate for these opposing tendencies, more and more assistance solutions are being used with an increasingly high level digitalization.

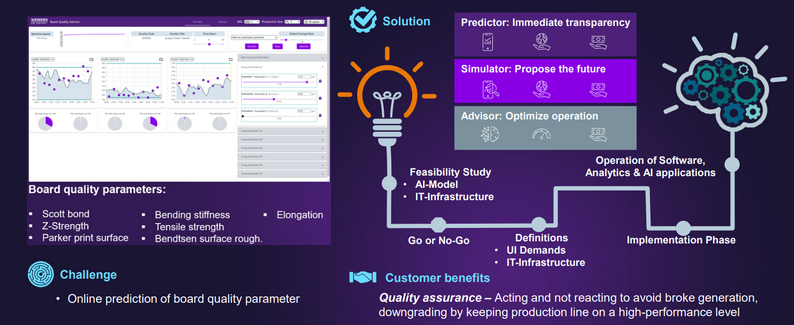

One assistance application that was initiated and developed a good three years ago in a joint pilot project with a carton board producer is the Board Quality Advisor. In the meantime, several board machines are running with the Board Quality Advisor and recognizes the positive benefits of this assistance system not only in qualitative terms.

With the Board Quality Advisor, the operator is in picture about his producing qualities in real time. For this to happen, all process data, both current and historical, from different data sources (process control system, laboratory values, manually entered values, recipes, limits, MES,…) are viewed, analyzed with AI, evaluated and processed. The Board Quality advisor can run as a tenant on a cloud platform and be used from there for various lines. It can also be used on premise or from a third party system. With the Board Quality Advisor the operator is enabled to act and not to react as before.

This circumstances is to be seen against the background that quality measurements are determined partly in the laboratory and take thus a certain time, which can take up to half or three quarters of an hour. During this time, the operator does not know whether he is still producing in accordance with the quality or whether he is already working out of the accepted range, in which case this may have to be down graded or even become broke. So far, the operator can only react when the quality measurements become known. With the Board Quality Advisor he acts and can ensure at any time that he produces the required product quality.

In the presentation the Board Quality Advisor is introduced as part of the assistance solutions of smart control family; it is explained the structure, which conditions must be given, how they are developed and with an on on-line demo the function mode will be presented as well as their use evaluated on basis installations.