Fuels from flue gas - biogenic advantage for pulp and paper mills

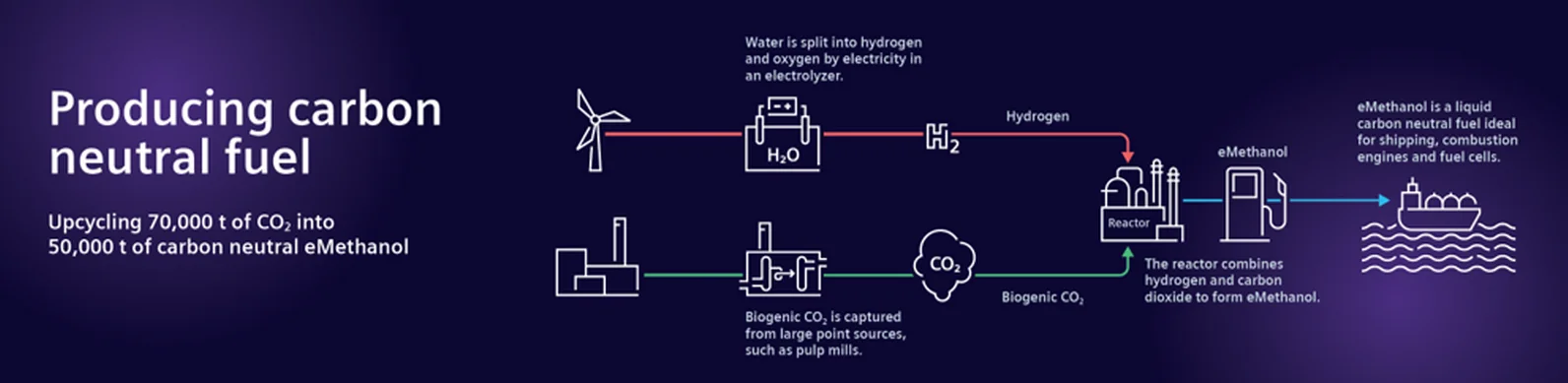

Green methanol is a driving force for industrial decarbonisation, and as a major emitter of biogenic CO2, the pulp and paper industry has an opportunity to reuse biomass-based (biogenic) CO2 for methanol synthesis. This methanol synthesis is based on green hydrogen and CO2 from biomass-based flue gas and is an enabler to increase the prospect of a carbon-neutral industrial system in pulp and paper mills or combined heat and power plants.

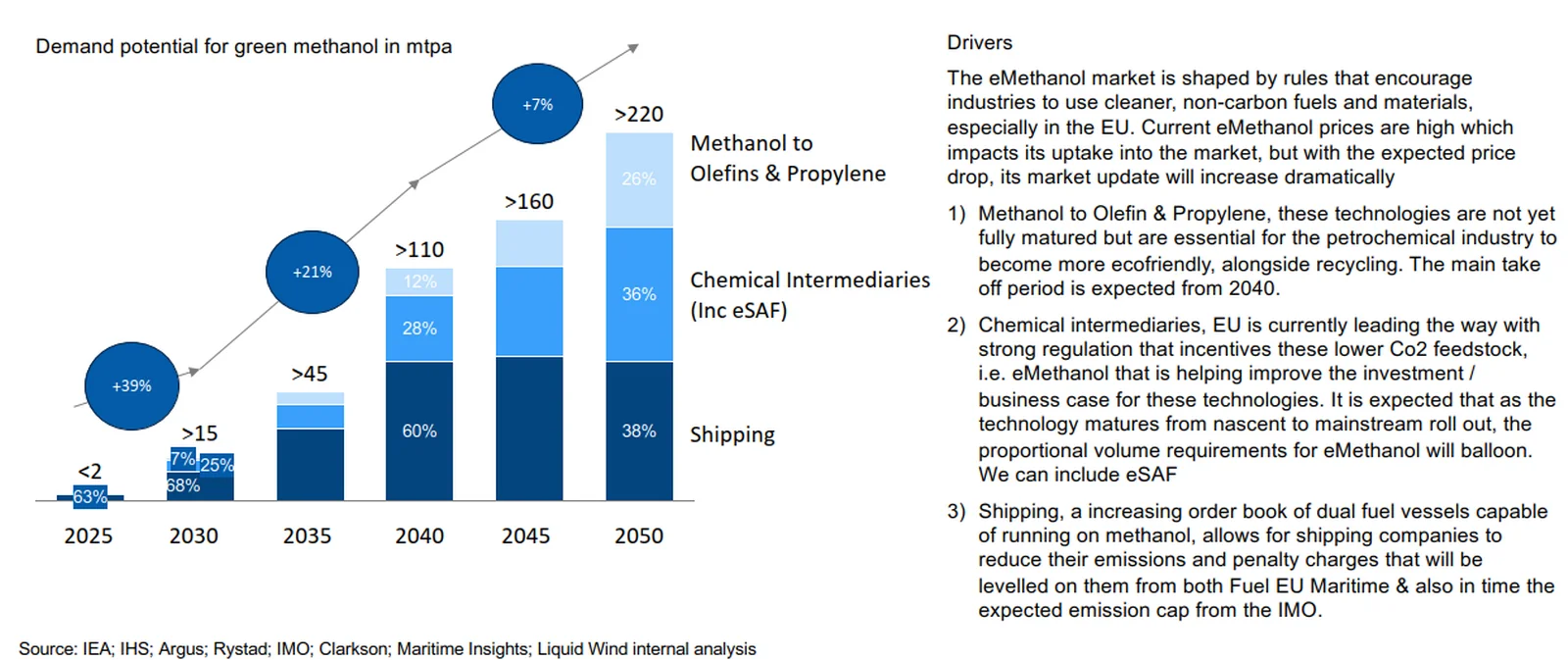

Methanol synthesis based on green hydrogen and CO2 from biomass flue gas offers the prospect of a carbon-neutral industrial system. As a fuel for mobility applications and a feedstock for the chemical industry, green methanol can make a significant contribution to the decarbonisation of shipping and other industries. At the same time, the integration of green methanol production into existing industrial facilities, such as pulp mills or combined heat and power plants, creates an opportunity to reuse a valuable resource such as biomass-based (biogenic) CO2, where the pulp and paper industry, as a major emitter of biogenic CO2, can play an even more important role in the transformation of the transport industry.

Production from water, green electricity and biogenic waste gases

The potential of this method lies in the fact that the biogenic CO2 emitted from, for example, biomass boilers or a lime kiln, can be recovered via a carbon capture process. This process avoids the emission of further climate-damaging carbon dioxide and uses it as a valuable resource and raw material for a new green energy carrier, such as eMethanol, a sustainable energy and, most importantly, generates the use of a biogenic CO2 sustainability loop, unlike if we were to use fossil-based CO2 emissions.

In addition, methanol synthesis produces water, oxygen (from the electrolysers) and waste heat, which can be used in a closed-loop system in the pulp mills. Oxygen is a valuable raw material in the pulp and paper industry, e.g. for the bleaching process, wastewater treatment or to increase the efficiency of other processes. Oxygen must either be produced on site at a high energy cost or purchased as a raw material from the market. Demineralised water from the pulp and paper process can be used in the electrolysis process as a feedstock for further hydrogen production.

Finally, due to highly efficient processes and state-of-the-art technology, modern pulp mills produce much more electrical energy than is needed for pulp production. Today, the surplus is either used in integrated pulp and paper mills or sold on the energy market for sometimes more, but usually less, profit.

Global roll-out of a model project

Liquid Wind, a Swedish power-to-fuel development company, together with Østed as investor, is currently building the world's first large-scale industrial roll-out of an e-methanol production plant, FlagshipONE. In addition, 100,000 t/a plants such as FlagshipTWO in Sundsvall, FlagshipTHREE in Umeå and FlagshipFOUR (2x 100,000 t/a) in Haapavesi/Finland are in the process of implementation and will be joined by 10 more Flagship plants in Europe by 2028, in partnership with CHP plants, waste incineration plants, bioethanol plants and hopefully soon also pulp and paper mills. The eMethanol produced will be used to power all types of vessels, replacing marine fuel oil.

The scale-up of the flagship projects will be supported by the Design & Performance Centre (DPC), which was inaugurated on 22 February in Hørsholm, Denmark. Liquid Wind and all OEM partners such as Siemens Energy. In the DPC, the Flagship "product" will be further modularised, standardised and enhanced with the latest technologies from the OEM partners, thus contributing to rapid scale-up, with the aim of developing and deploying 500 plants worldwide by 2050, helping to meet the much larger global demand for eMethanol.