First experiences with a new screening technology at heinzelpaper Laakirchen

Screening requirements have changed tremendously over the last years. Inferior raw material properties with higher levels of impurities for pulp and paper as well as increasing papermaking manufacturing costs, like energy and raw materials, have led to higher demands for more efficient products and to further process optimizations. Therefore, all paper makers must increase their effectiveness in order to compete and be sustainable in the globalized pulp and paper industry environment.

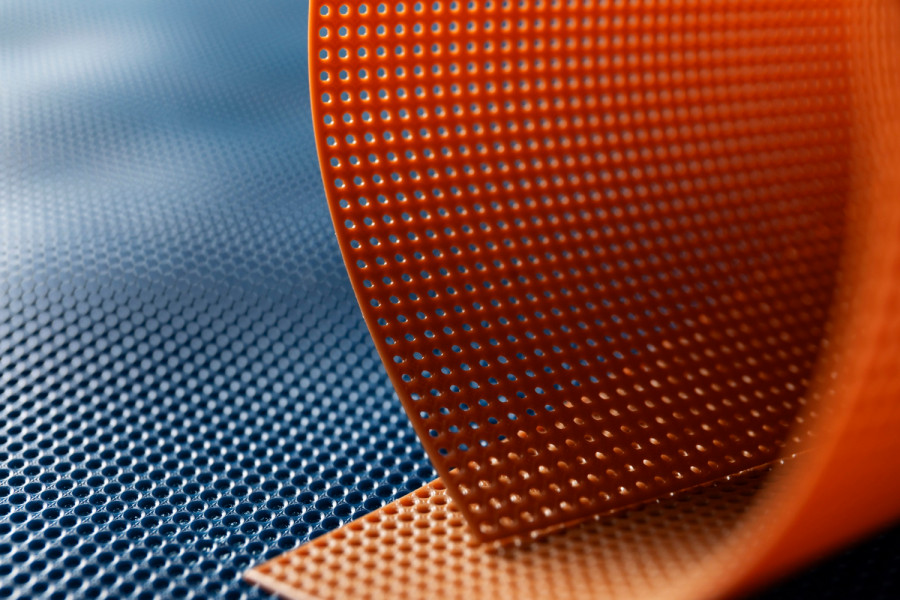

Based on this, Voith has developed a new profile basket, “We call it C-bar Vertecs”

In this presentation, the latest results and insights of this novel sorting technology will be shown. Flow analysis to extensive tests with laboratory investigations let to the new technology. To assess the StickyRemoval efficiency, we used both the established Ingede or Tappi methods, as well as the more informative NIR method. This also allowed for the analysis of the separation of microsticky fractions.

Several field tests reveal that the new screen basket invention boosts throughput by far over 20 % while maintaining or even enhancing the efficiency of sticky and dirt spec separation. This allows current screening sections to handle production constraints such as capacity and separation effectiveness. As a result, production rates are increased without compromising, and potentially even improving, the quality standard. In summary, we have established a new benchmark in screening reliability. The installation of a Vertecs screen basket allows a reduction in energy demand. With increased production by over 20 %, the rotor speed remains at its current speed. As a result, the energy used per ton in the screening process is effectively reduced.